June 1, 2023

WABA IS "BUILDING THE COMMUNITY ONE NEIGHBOR AT A TIME" WITH MANY PRODUCTS MADE RIGHT HERE IN THE COMMUNITY

Marathon County, WI has a rich history in logging and manufacturing of wood and paper products made possible with the rich timber resources have remained the leading industries in our area today. Many of the products by these and manufactures and others in the area are the products that are the supplies used to build and maintain our homes and the homes showcased in the Parade of Homes.

Window manufacturing is most likely the first to come to mind for most Marathon County residents. Our area has been deemed the "Window Capital of the World" by some. There is even an exhibit at the Marathon County Historical Society dedicated to the window industry here.

There are many other notable manufacturers of building supplies in our community that produce products that supply our community and beyond...some even supply to places around the globe! Here’s a quick look into some of them.

Menzner Hardwoods in Marathon CIty began it’s story in 1894. Currently, this company employs 500 individuals in 4 states to produce their moulding products.

- Menzner Hardwoods is a family-owned, fourth generation business since 1894, and we will be celebrating our 130th anniversary next year.

- We employ 500 employees across 4 states – Wisconsin (Headquarters), Kentucky, Mississippi, and South Carolina.

- Our main office headquarters is located in one of the original homes built in Marathon in 1875.

- “The two and a half story, red brick, Italianate Fricke House was built by Henry Fricke. Fricke is known as the first person to harness the Rib River successfully, making it possible to settle in Marathon. Today, the house, later known as the Fricke-Menzner house, houses the offices for Menzner Hardwoods.”

- We process over 22 million board feet of lumber per year.

- This summer we are opening our brand-new state of the art Rough Mill (lumber

processing facility) that has been completely renovated and updated with new equipment and technology.

Julie works as a Back-up Moulder Operator, but also assists in many other areas of the plants. Julie’s favorite part of her job is the freedom and flexibility to work wherever she is needed.

Corey is a Back-up Moulder Operator in the Moulding Department. His favorite aspect of his job is learning new things each and every day.

______

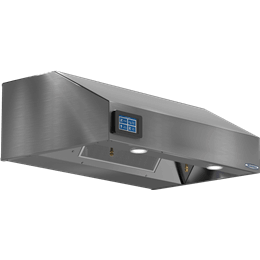

Greenheck produces products for commercial, industrial, and residential building needs. The products most often used in residential settings would be their kitchen exhast hoods and ceiling exhaust fans.

- They have eight facilities around the globe.

- Greenheck was founded in 1947, making the company 76 years old.

- Forbes named Greenheck Group one of America’s Best Midsized Employers in 2021.

- Greenheck’s products are available in the United States and Canada through a network of manufacturer’s reps. They also have representatives in the following countries: Algeria, Argentina, Australia, Bahrain, Brunei, Caribbean, Chile, China, Colombia, Costa Rica, Cyprus, Ecuador, Egypt, El Salvador, Emirates, Guam, Guatemala, Hong Kong, India, Indonesia, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Lebanon, México, Oman, Pakistan, Panamá, Perú, Puerto Rico, Qatar, Saudi Arabia, Singapore, South Korea, Sri Lanka, Taiwan, Thailand, The Philippines, Turkey, United Arab Emirates, United Kingdom, Venezuela, and Vietnam.

______

- The Kolbe brothers began building window sash in their mother’s wash house on a dairy farm in Marathon, Wisconsin.

- Today Kolbe has approximately 1,000 team members and 2 manufacturing campuses in Wisconsin (Wausau & Manawa).

- Kolbe products can be styled from contemporary to traditional with some windows and doors featured in locations on the National Register of Historical Places around the US.

- Kolbe purchased an antique trolley from the city of Wausau in 1994 and restored it for transportation in parades and special events.

- The prominent blue of Kolbe’s delivery trucks was Herb Kolbe’s favorite color.

"I have been with Kolbe since 1986, and have enjoyed all my roles, from drilling side stops to working in Quality Assurance, to my current role as a foreperson. I enjoy mentoring and assisting team members in daily tasks and challenges and feel great at the end of the day knowing I have helped someone produce a quality-crafted product for homeowners in our local neighborhoods and across the country. As a mentor, I encourage all team members to continue learning and doing their very best every day to be proud of their work and skills, build a quality product, grow as a team, and help create a stronger community."

Connie Schulz

Kolbe Assembly Foreperson

Luke Skadahl

Kolbe ServicePro Manager

______

- In 2001, through an Employee Stock Ownership Plan (ESOP), Wausau Supply Co. sold the company to its employees and, in 2015, became 100% employee-owned.

- The Schofield, Wisconsin manufacturing facility has expanded multiple times making it the largest single building in Marathon County.

- Wausau Supply has 25 facilities that supply retail centers throughout the United States.

Mark, Technical Supervisor in the Coatings Department, says his favorite thing about Wausau Supply is that it is a big group of people who all just want to do the right thing.

Business Development Analyst, Jimmy, says his favorite thing about Wausau Supply is the culture of helpfulness.